Streamlining Warehouse Picks with Visual SKU Matching

Introduction – When “Close Enough” Isn’t Good Enough

In today’s fast-moving e-commerce and logistics world, customers expect every order to arrive on time and with the correct items inside. But in busy warehouses — especially those dealing with hundreds or thousands of similar-looking products — mistakes happen. A picker might grab the wrong size, color, or variant of a product. These small errors lead to big problems: delays, returns, refunds, and negative reviews.

Traditional barcode scanners and manual checks aren’t always enough. They rely on human accuracy, which naturally slips during long shifts or peak seasons. The consequences ripple across the entire operation — extra shipping costs, wasted labor, lost trust, and a damaged brand reputation.

That’s where visual SKU matching steps in. This technology uses cameras combined with computer vision to automatically verify that the right item is picked at the right time. As soon as a worker lifts a product off the shelf, a camera captures the image, identifies the item, and compares it to the expected SKU from the warehouse management system (WMS). If there’s a mismatch, it’s caught immediately — before the item even reaches the packing station.

This real-time verification closes the gap between intention and execution. With vision-powered picking, warehouses dramatically reduce errors, speed up fulfillment, and increase customer satisfaction. It’s not just a tech upgrade — it’s a shift in how modern logistics protects accuracy at scale.

In this blog post, we’ll explore how visual SKU matching works, the technology behind it, and how businesses are using it to reduce costs, improve reviews, and stay competitive in 2025 and beyond.

The Hidden Cost of Mis-Picks in 2025 Fulfillment

At first glance, a single wrong item in a shipment might seem like a minor slip. But when you look at the full cost of a picking error, the impact is much greater than it appears. In today’s fulfillment centers — where speed is essential and customers expect near-perfect accuracy — every mis-pick can trigger a chain of expensive consequences.

Let’s break it down:

Returns and Refunds: When a customer receives the wrong item, they usually send it back. That means the business pays for return shipping, handling, and restocking. These costs add up fast — especially when it happens at scale.

Replacements and Reshipping: Sending out the correct item after a mistake means paying for another round of shipping and packaging. If the product was time-sensitive (like a birthday gift or seasonal item), delays can’t be undone.

Wasted Labor: Every mistake pulls warehouse staff off-task. Workers spend time processing returns, correcting orders, and resolving customer complaints instead of fulfilling new shipments.

Damaged Customer Trust: Perhaps the biggest hidden cost is the loss of customer loyalty. One bad experience can lead to negative reviews, lower satisfaction ratings, and fewer repeat purchases. In competitive markets, even a small dip in trust can lead to long-term revenue loss.

Research shows that return rates in e-commerce can range from 15% to 30%, and picking errors are a common reason. In industries like apparel, cosmetics, and electronics — where SKUs look very similar — mis-picks are even more frequent.

As order volumes increase and inventory becomes more complex, the risk of error also grows. Many warehouses are now dealing with SKU sprawl — thousands of nearly identical items with subtle differences in color, size, branding, or packaging. Relying solely on humans to spot these differences is no longer practical or scalable.

That’s why leading fulfillment teams are turning to automation, and specifically to visual SKU matching. It’s a way to stop errors before they leave the shelf — protecting profits, efficiency, and reputation all at once.

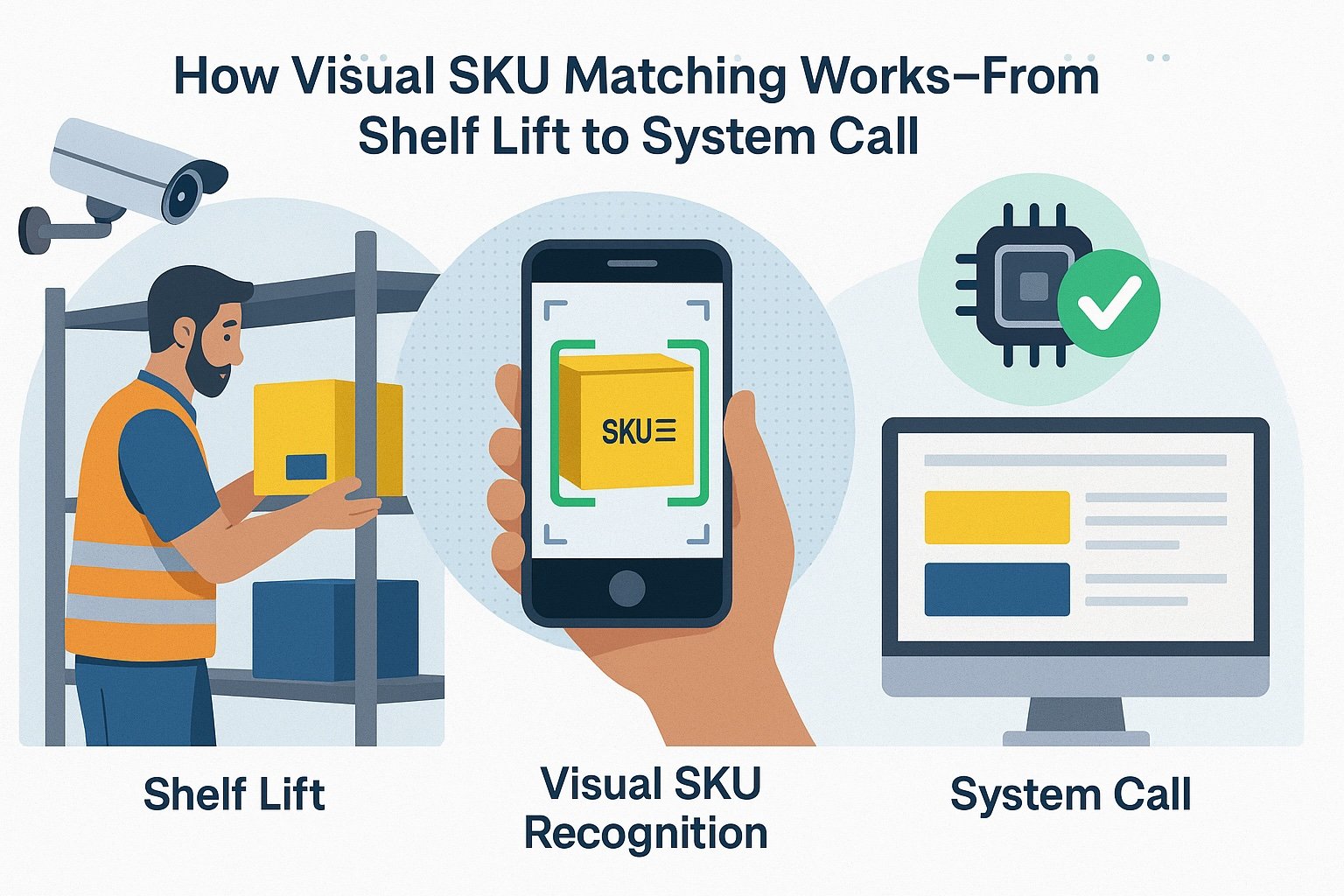

How Visual SKU Matching Works — From Shelf Lift to System Check

Visual SKU matching sounds futuristic, but the process is surprisingly straightforward when broken down. It uses a combination of cameras and AI to double-check that the item picked from the shelf is exactly what was ordered. The goal is to catch mistakes in real time — before the wrong item reaches packing, or worse, the customer.

Here’s how it works step by step:

Step 1: Detect the Item Being Picked

A camera — either mounted above the shelf or worn on the worker’s wrist or vest — watches for movement. When an item is lifted from the shelf, the system detects this action and snaps a photo or short video of the object.

Step 2: Focus on the Product Itself

Using object detection algorithms, the system identifies the area in the image that contains the item. This step filters out the background, worker’s hands, and shelf details. The result is a clean, focused view of the picked item.

Step 3: Analyze the Product’s Appearance

Now, computer vision tools go to work:

Image recognition looks at the object’s shape, color, size, and packaging.

Logo or label detection identifies brand marks or visual patterns.

OCR (Optical Character Recognition) reads any printed text, such as serial numbers, SKU codes, or product names.

These combined results are used to determine which product was picked — down to the exact SKU level.

Step 4: Match Against the WMS Pick List

The system compares the recognized item against the warehouse management system (WMS), which knows what item the picker should have grabbed. If it’s a match, the process continues as usual. If there’s a mismatch — say the wrong color or model — it flags the issue instantly. The picker can be alerted through a light, beep, or wearable display, allowing them to fix the error right away.

Step 5: Record the Event

Every verified pick can be logged with a timestamp and thumbnail image. This creates an audit trail for quality control and training purposes. If there’s ever a dispute, managers can see exactly what was picked and when.

This entire process can happen in under a second, thanks to edge computing and optimized AI models. Vision APIs — like those for object detection, OCR, and brand/logo recognition — are the key building blocks that make this possible. When connected properly, they give warehouses a reliable, automated second set of eyes.

Visual SKU matching doesn’t slow pickers down — in fact, it makes them faster and more confident. Instead of second-guessing or double-checking labels, workers simply pick and go, knowing the system has their back. And when errors are caught early, the entire fulfillment operation runs smoother, faster, and more accurately.

Building the Tech Stack Without Reinventing the Wheel

One of the best things about visual SKU matching is that it doesn’t require building everything from scratch. Most warehouses can start small and grow their system over time using off-the-shelf components and cloud-based APIs. Whether you’re a fulfillment center shipping 500 or 50,000 orders a day, a modular tech stack makes visual verification practical and cost-effective.

Let’s take a closer look at the main pieces of the puzzle.

Cameras: The Eyes of the System

The first step is capturing a clear image of the picked item. Depending on your setup, this can be done with:

Fixed industrial cameras mounted above pick zones or shelves.

Wearable cameras attached to a picker’s wrist, chest, or glasses for more mobility.

Key camera features include:

High frame rates (30–60 FPS) to avoid motion blur.

Decent resolution (at least 1080p) for reading labels and text.

Global shutter (instead of rolling shutter) if the items are in motion.

Lighting also plays a big role — consistent LED lighting helps avoid shadows and reflections that can confuse vision models.

AI Software & APIs: The Brain of the System

Once you have an image, you need software that can understand what’s in it. That’s where computer vision APIs come into play. Instead of building and training your own models from scratch, you can use ready-to-go endpoints to handle core tasks like:

Item Detection

→ Use an Object Detection API to find the exact location of the item in the image.Label & Variant Recognition

→ Use an Image Labelling API to identify the product type, variant, or SKU.Text and Barcode Reading

→ Use an OCR API to extract model numbers, serial codes, or SKU text directly from packaging.Brand and Logo Recognition

→ Use a Brand & Logo Recognition API to verify if the correct brand has been picked — especially helpful in white-label or multi-brand warehouses.Privacy Protection

→ Use an Image Anonymization API to blur worker faces or sensitive areas automatically, keeping your operation GDPR and CCPA compliant.

All these APIs can be connected via standard REST calls, making integration fast and flexible. And if your SKU formats or packaging are unique, some providers (like API4AI) offer custom model training tailored to your exact product catalog.

Edge or Cloud? Choosing Where Inference Happens

Depending on your infrastructure and internet speed, you can run the recognition pipeline either:

In the cloud, for easy scaling and central control, or

At the edge, using a small on-site server or gateway to reduce latency and keep operations running even without internet.

Both approaches are valid. For large operations with strict latency goals, edge computing might be preferred. For smaller warehouses or those already cloud-native, a cloud API setup is usually faster to deploy.

Start Simple, Scale Later

You don’t need to build a perfect system from day one. Many operations begin by using cameras only in high-risk areas — like SKUs with frequent mix-ups or new employee zones. Over time, the same tech can expand to cover all pick zones or even packing stations.

Thanks to flexible APIs and plug-and-play hardware, adding visual SKU matching to your warehouse doesn’t mean a full infrastructure overhaul. Instead, it’s a smart layer of protection that fits into your current process — and grows as your business grows.

Plugging Vision Checks into Your WMS & Pick-to-Light Flow

Once you have cameras and computer vision models running, the next step is to connect everything to your warehouse systems. The good news? Visual SKU matching can fit into most existing workflows without major changes. Whether you use pick-to-light, voice picking, or a handheld scanner setup, vision-based verification adds a smart safety net without slowing things down.

Connecting with Your WMS (Warehouse Management System)

Your WMS knows what each picker should grab from the shelf. To make visual checks work, the system needs to compare this expected SKU with what the camera sees. This is done by setting up simple connections between the WMS and the vision pipeline.

Here’s how it typically works:

The WMS sends the expected SKU data to the vision system for each pick task.

After a picker lifts the item, a camera captures an image.

Computer vision APIs analyze the item and return a recognition result.

The result is compared against the expected SKU.

If it's a match, the WMS marks the pick as successful.

If it's a mismatch, the system flags the issue so the picker can correct it.

This entire loop happens in seconds and works smoothly in both high-speed and low-volume environments.

Enhancing Pick-to-Light and Voice Picking Systems

Many modern warehouses use pick-to-light systems — shelves with lights that guide pickers to the correct item location. Visual SKU matching adds a second layer of confirmation. Once the picker grabs the item indicated by the light, the system uses the camera to verify that the right product was picked before allowing the process to continue.

In voice picking setups, workers wear headsets and receive verbal instructions about what to pick. Vision systems can quietly verify the pick in the background without needing any extra steps from the picker.

The result? Fewer mistakes, no manual double-checking, and a smoother experience for your team.

Dealing with Exceptions in Real Time

Sometimes, mistakes happen — a worker grabs the wrong color, the wrong size, or picks two items instead of one. With visual SKU matching in place, these errors are caught immediately.

The system can respond by:

Beeping or flashing a warning light

Sending a message to the picker’s handheld device or headset

Notifying a supervisor for review

Automatically generating a correction task in the WMS

This helps fix problems instantly, without slowing down the rest of the shift or creating delays later in packing or shipping.

Attaching Visual Proof to Every Pick

Another major benefit is traceability. Every verified pick can include a thumbnail image or video snippet that’s stored alongside the pick record in the WMS. If a customer claims they received the wrong item, you have visual proof of what was picked and when.

This creates:

A clear audit trail for quality control

Useful data for training new employees

Peace of mind for customer support and returns handling

Secure, Compliant, and Scalable

Visual SKU matching systems can be secured with:

Role-based access control for users

API keys and token-based authentication

GDPR/CCPA-compliant data handling, especially if employee faces or work areas are captured

These integrations can be scaled gradually — starting with a few pick zones and expanding as your confidence grows. Thanks to modern APIs and cloud-native tools, connecting vision to your warehouse systems is easier than ever.

With everything wired together — your cameras, APIs, and WMS — you gain a smart, fast, and reliable way to catch errors before they cause trouble. Visual checks become just another part of your workflow — but one that quietly saves time, money, and customer trust with every order.

KPIs & ROI — Proving the Business Case in 90 Days

Adopting visual SKU matching isn’t just about adding cool technology — it’s about delivering real, measurable results. For any warehouse considering the investment, it's important to understand which performance indicators to track and how quickly the return on investment (ROI) can be seen.

When set up correctly, visual SKU matching begins to pay for itself in just a few weeks. Let’s look at how to measure success and what kind of impact you can expect.

Key Performance Indicators (KPIs) to Track

To prove the value of visual verification, focus on the following metrics:

Pick Accuracy (%)

This is the core KPI. It shows the percentage of orders picked without any errors. With vision checks in place, many warehouses see accuracy jump from ~97% to 99.9% or higher.Return Rate (%) Due to Mis-Picks

Tracking how many returns happen because the wrong item was shipped gives a direct view of improvement. A drop in return rates leads to real savings.Average Order Cycle Time

This is the time from pick start to order completion. Vision systems reduce the need for manual double-checks, so orders move faster.Customer Satisfaction (CSAT) and Reviews

Fewer mistakes lead to better reviews, higher star ratings, and improved repeat business. You can measure CSAT through post-order surveys or public review platforms.Labor Hours Spent on Corrections

Monitor how many hours are spent fixing pick errors — processing returns, reshipping items, or answering support tickets. With fewer errors, this number drops significantly.

Estimating the ROI with Simple Math

Let’s take a common scenario:

Your warehouse ships 50,000 orders per month

The current pick error rate is 1%, which means 500 wrong orders

Each mis-pick costs about $15 (including return shipping, restocking, customer support, and resending the item)

That’s $7,500 per month in avoidable costs

If visual SKU matching reduces that error rate to 0.2% (just 100 mistakes), your new cost is $1,500 — a savings of $6,000 per month.

Multiply that over a year, and you’ve saved $72,000 — and that’s not even counting the long-term benefits of better reviews and more repeat customers.

Additional Operational Benefits

Beyond the obvious numbers, vision-driven picking brings softer but still valuable improvements:

Faster onboarding

New employees need less time to memorize product shapes and labels because the system helps them avoid errors automatically.Data for continuous improvement

Managers can review image logs to spot patterns, such as specific items or locations that cause more errors.Proof of quality control

Having visual records makes it easier to show auditors, partners, or enterprise clients that your operation is built on accuracy and traceability.

Start Small, Show Results Fast

You don’t have to roll out visual SKU matching across your entire warehouse on day one. Start with a few shelves, a single pick zone, or one product category that’s prone to errors. This way, you can prove the value quickly and scale based on clear performance wins.

By focusing on the right KPIs and measuring results early, it’s easy to demonstrate how visual SKU matching isn’t just an upgrade — it’s a high-impact investment that cuts waste, boosts trust, and helps fulfillment operations run smarter every day.

Conclusion – Vision-Powered Picking Becomes the New Standard

In a world where customers expect fast, flawless delivery, small mistakes in the warehouse can lead to big consequences. Missed picks don’t just create more work — they erode trust, damage your brand, and eat into already thin margins.

Visual SKU matching offers a powerful, practical way to fix this problem before it starts. By combining cameras with intelligent image recognition, it turns every pick into a smart, verified action. Mistakes are caught in real time. Returns go down. Reviews go up. And your entire fulfillment process becomes faster, cleaner, and more reliable.

The best part? You don’t need to overhaul your entire warehouse or hire a team of data scientists to get started. With cloud-ready APIs like object detection, OCR, image labeling, and logo recognition — along with camera setups that are easy to deploy — you can start small and scale with confidence. Tools like the Object Detection API, OCR API, and Brand & Logo Recognition API from providers such as API4AI make it possible to quickly build a custom vision system that fits your exact needs.

From improving pick accuracy and cutting returns, to helping new employees succeed faster, visual verification adds a modern layer of control that warehouses need to stay competitive in 2025 and beyond.

The bottom line? If your business relies on accurate order fulfillment, now is the time to stop relying on human eyes alone. Let computer vision be your second set of eyes — and your new edge in smarter, more accurate warehousing.