AI Object Detection API: Key to Automated Quality Control

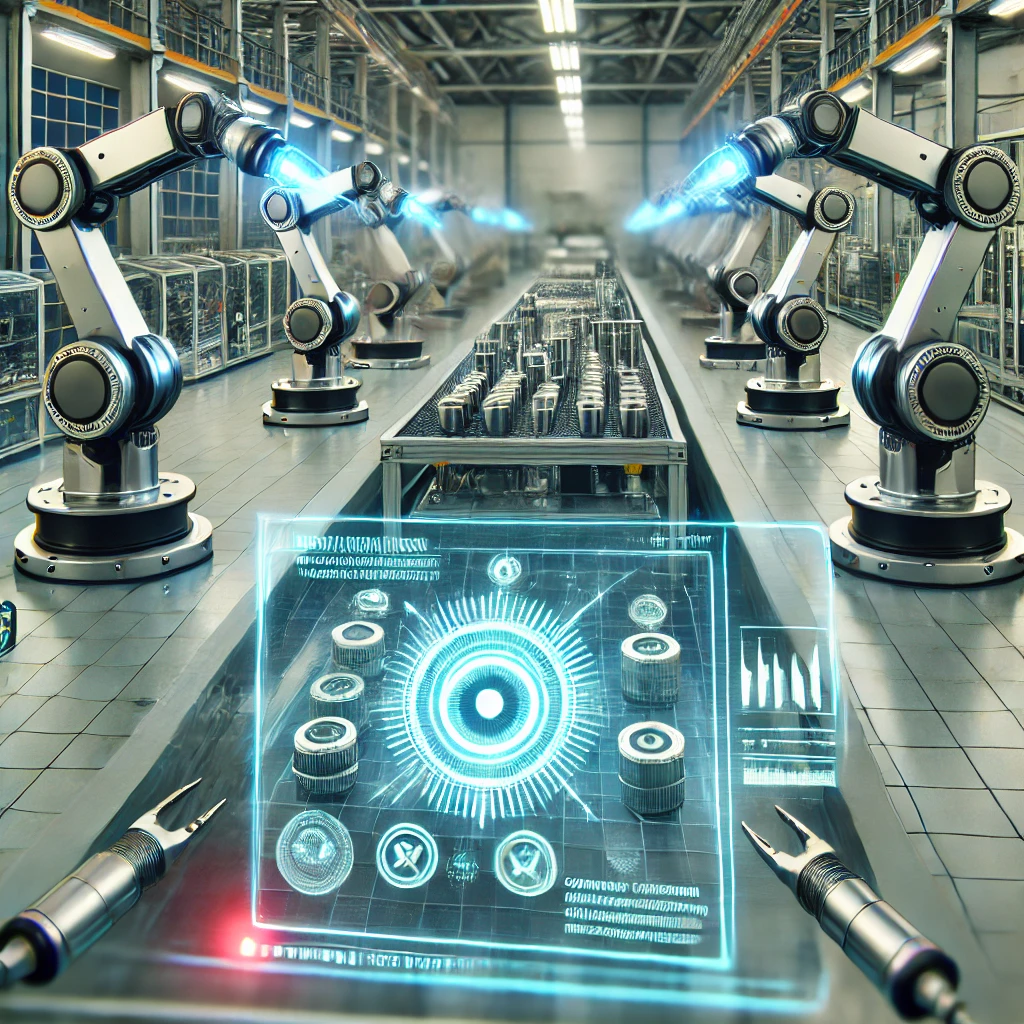

In today’s fast-paced manufacturing environment, maintaining consistent product quality is more critical — and more challenging — than ever. AI-powered object detection is emerging as a powerful solution, enabling real-time identification of defects, reducing human error and streamlining quality control processes across industries. This blog post explores how manufacturers in sectors like electronics, automotive and food and beverage are using automated visual inspection to boost accuracy, scalability and efficiency. Learn about the key benefits, real-world applications and best practices for implementing object detection systems and discover how embracing AI today can lead to long-term profitability, reduced waste and stronger brand trust. Whether through ready-to-use APIs or custom computer vision solutions, the future of manufacturing quality control is here — and it’s intelligent, adaptable and automated.

Quality Control 2.0: Detect Defects Faster with Deep Learning Models

Quality control is entering a new era with the power of deep learning. Traditional inspection methods, limited by human error and inefficiency, are being replaced by AI-driven manufacturing solutions that deliver unparalleled speed, precision and scalability. From detecting micro-defects in electronics to automating label inspections in pharmaceuticals, defect detection automation is transforming industries. Explore how deep learning revolutionizes quality control, its applications across sectors and why adopting AI-powered solutions is key to staying competitive in today’s fast-paced manufacturing world. The future of quality control is here — are you ready to embrace it?

Transforming Quality Control with Computer Vision

Traditional quality control methods struggle to keep up with the demand for precision and efficiency. Computer vision is transforming this landscape by automating inspections, detecting even the smallest defects and ensuring product consistency across industries. From real-time monitoring on production lines to customized solutions for niche markets, this AI-powered technology is setting new standards for quality assurance. Discover how computer vision is shaping the future of quality control and why adopting this innovation is essential for staying competitive in an evolving market.