How AI-Powered Image Recognition APIs Enhance Quality Control in Manufacturing

Introduction

In today’s highly competitive manufacturing landscape, maintaining top-tier product quality is more critical than ever. Quality control (QC) plays a pivotal role in ensuring that products meet both industry standards and customer expectations. Effective QC processes help manufacturers reduce defects, lower costs, and enhance customer satisfaction. Traditionally, this has been achieved through manual inspection or rule-based automation systems, both of which come with significant limitations. Manual inspections are prone to human error and inefficiency, while rule-based systems often struggle to keep up with the complexity and variability of modern production environments.

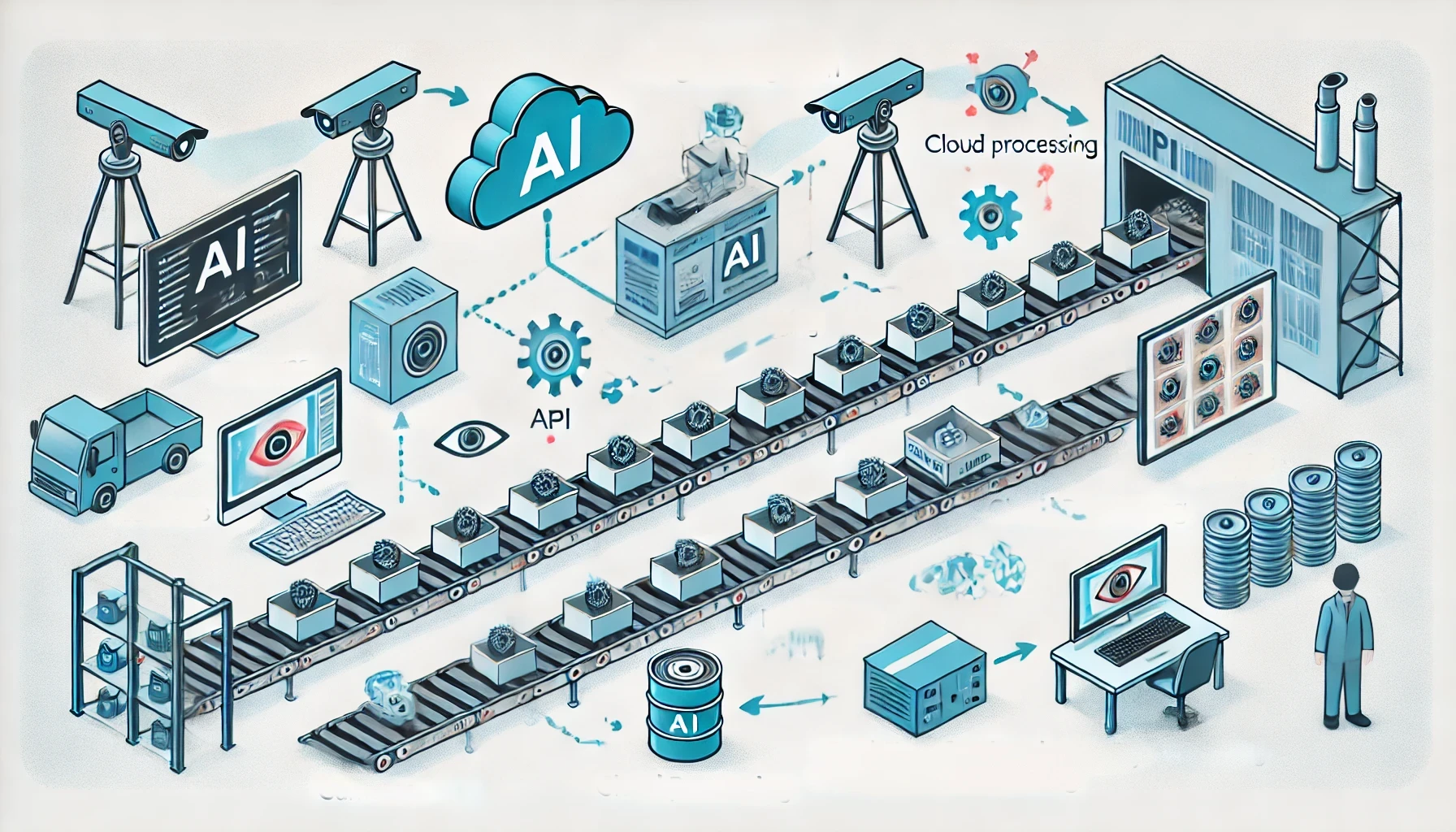

However, the emergence of artificial intelligence (AI) is revolutionizing quality control in manufacturing. Specifically, AI-powered image recognition is offering unprecedented levels of accuracy and efficiency. By leveraging machine learning models, image recognition APIs can automatically detect defects, verify component placement, and ensure product consistency in real-time. These systems go beyond traditional automation by being able to learn, adapt, and improve over time, making them more versatile in handling diverse and complex production lines.

AI-powered image recognition APIs are not only powerful but also highly accessible to manufacturers. These cloud-based APIs offer seamless integration into existing production workflows, allowing manufacturers of all sizes to benefit from cutting-edge technology without requiring significant in-house expertise. As a result, manufacturers can enhance their quality control processes, reduce defects, and ultimately improve operational efficiency and product quality.

By embracing AI-powered image recognition, manufacturers can stay competitive in an increasingly automated industry, where precision and speed are key drivers of success.

The Role of Image Recognition in Quality Control

What is Image Recognition in the Context of Manufacturing?

In manufacturing, image recognition refers to the use of advanced AI algorithms to identify, classify, and detect objects within an image. This technology has become a game-changer for quality control, enabling manufacturers to automate inspection processes and ensure product consistency. By analyzing images of products in real-time, AI-powered image recognition systems can detect defects, verify component placement, and ensure that assemblies meet specified standards.

Core functionalities of image recognition in manufacturing include:

Identifying products and parts by comparing them to a reference image or model.

Classifying objects based on predefined categories, such as detecting specific types of defects (an example - Image Labeling API).

Detecting objects and abnormalities, such as surface defects (scratches, dents), missing components, or misalignments during assembly (an example - Object Detection API).

This technology is widely used in various quality control applications, including:

Surface defect detection: Ensuring products have no visible imperfections such as scratches, dents, or discoloration.

Component inspection: Verifying that all necessary components are present and correctly placed in the assembly process.

Assembly validation: Ensuring that assembled products meet design specifications and standards before proceeding to the next production stage.

Key Benefits of Image Recognition for Quality Control

The adoption of AI-powered image recognition APIs offers several advantages over traditional quality control methods, enhancing both accuracy and operational efficiency.

Accuracy and Precision

One of the primary benefits of AI-powered image recognition in manufacturing is its ability to detect even the most subtle defects that may be missed by human inspectors or rule-based automation systems. Whether it’s a small scratch on a surface or a minor misalignment in assembly, AI systems can analyze images with a level of detail and precision that surpasses manual inspection. This leads to higher product quality and fewer defects making it through to the final stages of production.Speed and Scalability

In a fast-paced manufacturing environment, speed is crucial. AI image recognition operates in real-time, allowing manufacturers to quickly analyze images and make immediate adjustments to the production line when necessary. Moreover, these systems can be scaled to handle high volumes of production, making them ideal for large-scale operations. With the ability to process hundreds or thousands of images per second, image recognition APIs help maintain productivity without sacrificing quality.Reduction of Human Error and Labor Costs

Manual inspection processes are not only time-consuming but also prone to human error, especially when repetitive tasks are involved. By automating the quality control process through AI image recognition, manufacturers can significantly reduce the risk of mistakes and inconsistencies. Additionally, automating these inspections leads to a reduction in labor costs, as fewer workers are needed for quality control tasks, freeing up resources for other critical areas of production.

AI-Powered Image Recognition APIs: How They Work

How Image Recognition APIs Integrate Into Existing Quality Control Systems

AI-powered image recognition APIs are designed for seamless integration into existing quality control workflows, offering manufacturers an efficient way to enhance their inspection processes without a complete overhaul of current systems. These APIs are built with flexible, API-based infrastructure, allowing easy integration with a wide range of manufacturing software ecosystems, including MES (Manufacturing Execution Systems), ERP (Enterprise Resource Planning), and custom automation systems. This compatibility makes it simple to incorporate advanced image recognition capabilities into both legacy and modern systems.

Manufacturers also have the option to choose between cloud-based or on-premise solutions based on their specific needs:

Cloud-based APIs provide the advantage of scalability, allowing manufacturers to process and analyze vast amounts of image data with minimal hardware investment. Cloud solutions are ideal for businesses that need flexibility and are looking to scale their operations quickly.

On-premise solutions, on the other hand, offer greater control over data privacy and security, making them a suitable choice for industries dealing with sensitive information or requiring compliance with strict regulations. On-premise systems can also be customized to meet the unique demands of specific production lines.

The flexibility of these options allows manufacturers to implement AI-powered image recognition in a way that best fits their operational and security requirements.

Technical Capabilities of AI Image Recognition APIs

AI-powered image recognition APIs offer a range of powerful technical capabilities that are transforming quality control in manufacturing:

Object Detection, Anomaly Detection, and Classification in Real-Time

These APIs excel in real-time analysis, enabling manufacturers to detect objects, identify defects, and classify products instantaneously. For example, object detection can verify whether a component is correctly assembled, while anomaly detection can identify defects such as surface scratches, dents, or irregular shapes. This real-time feedback allows production teams to correct issues immediately, preventing defective products from progressing through the manufacturing line.Self-Improvement Through Training and Machine Learning

One of the key advantages of AI-powered image recognition is the ability of the models to self-improve over time. Through continuous learning, these APIs can be trained on new datasets, refining their accuracy and adapting to changing production environments. As the system processes more images, it becomes better at recognizing patterns, distinguishing between acceptable variations and true defects, and handling edge cases more effectively. This ability to learn and improve ensures that the system stays up-to-date with evolving production needs.Handling Edge Cases and Variation

Manufacturing environments are often subject to variability in lighting, product orientation, and other factors that can affect the quality of inspections. AI image recognition APIs are designed to handle these edge cases with high precision. For instance, they can adapt to changes in lighting conditions or detect defects in products that are presented at varying angles. This robustness makes AI-powered image recognition more reliable than traditional rule-based systems, which can struggle with inconsistencies and environmental changes.

By providing real-time object and anomaly detection, the ability to continuously improve through machine learning, and handling edge cases with precision, AI-powered image recognition APIs offer a comprehensive solution for enhancing quality control in manufacturing.

Key Use Cases in Manufacturing Quality Control

Defect Detection

One of the most critical applications of AI-powered image recognition APIs in manufacturing is defect detection. Surface inspection systems using AI can identify even the most subtle imperfections, such as scratches, dents, cracks, or discoloration, which could otherwise go unnoticed in traditional inspections. By analyzing each product’s surface in real-time, AI-driven systems can flag any anomalies that do not meet the required quality standards, ensuring defective products are caught early in the production process.

Case study/example: In the automotive industry, AI image recognition is used to inspect the exterior paint finish of vehicles for imperfections, ensuring a flawless appearance before the vehicles leave the assembly line. Similarly, in electronics manufacturing, AI systems inspect the surfaces of devices like smartphones and laptops for scratches or dents, ensuring that the final products meet strict cosmetic and functional standards.

Assembly Verification

In complex manufacturing processes, ensuring that each component is correctly placed is vital to both product function and safety. AI-powered image recognition APIs excel in assembly verification, helping manufacturers ensure that all components are properly assembled. By using advanced object detection, these systems can automatically verify that each part is in the correct position and orientation before moving the product further down the assembly line.

Example: In PCB (Printed Circuit Board) assembly lines in electronics manufacturing, AI image recognition is used to verify the placement of tiny components like resistors, capacitors, and microchips. Even the slightest misplacement can lead to functional defects, but AI can detect these errors in real-time, allowing for immediate corrections and minimizing rework costs.

Dimensional Measurement and Tolerance Checks

Maintaining precise dimensions and adhering to tight tolerances are crucial in industries like aerospace, medical devices, and precision engineering. AI-powered image recognition helps manufacturers conduct dimensional measurementsand verify that products meet strict specifications. By analyzing the size, shape, and geometry of parts, AI systems can ensure they fall within acceptable tolerance levels.

Example: In aerospace engineering, components such as turbine blades and aircraft parts must meet exact specifications to ensure safety and performance. AI image recognition systems are used to measure these components and verify they adhere to stringent dimensional tolerances, preventing defects that could compromise product integrity.

Packaging and Labeling Inspection

Ensuring that products are correctly packaged and labeled is a key part of quality control in manufacturing, especially for industries where compliance and brand consistency are critical. AI-powered image recognition APIs can automatically inspect packaging and labeling, ensuring that products are packaged according to standards and that labels are correct and readable.

Example: In the food and beverage industry, AI systems inspect packaging for seal integrity, ensuring no damage or contamination. Additionally, they verify that labels include the correct information, such as expiration dates and nutritional facts, before products are shipped to retailers. This minimizes the risk of compliance issues and ensures brand consistency on store shelves.

Advantages Over Traditional Quality Control Methods

Consistent and Objective Inspections

One of the biggest advantages of AI-powered image recognition APIs over traditional quality control methods is their ability to provide consistent and objective inspections. Human inspectors, while experienced, are prone to fatigue, distraction, and bias, all of which can lead to inconsistent results and missed defects. In contrast, AI systems operate with unwavering precision, analyzing each product with the same level of accuracy regardless of time or conditions. This eliminates the variability introduced by human factors, ensuring that each inspection meets the same high standard.

By utilizing machine learning algorithms, AI-powered systems can accurately detect defects and inconsistencies that might escape human detection, resulting in higher-quality products and fewer errors making it through to the customer.

Adaptability and Customization

AI-powered image recognition APIs offer unparalleled adaptability and customization, allowing manufacturers to tailor quality control processes to meet specific needs. These APIs can be trained and fine-tuned to recognize particular products, components, or defect types, making them highly versatile across various industries and applications. Whether a manufacturer is producing consumer electronics, automotive parts, or medical devices, AI systems can be customized to identify and address the unique challenges of each production line.

Additionally, as product designs and manufacturing processes evolve, AI systems can be retrained with new datasets, enabling them to adapt to changes in the production line. This flexibility allows manufacturers to continuously improve their quality control processes, keeping pace with innovation and market demands.

Real-Time Data Collection and Analysis

A significant advantage of AI-powered image recognition is the ability to conduct real-time data collection and analysis. These systems not only detect defects but also provide actionable insights that allow manufacturers to make immediate corrective actions. When a defect is identified, production teams can instantly respond to the issue, whether by adjusting machine settings, removing defective products, or making other necessary interventions.

AI image recognition APIs can also be integrated with IoT (Internet of Things) sensors and predictive analyticsplatforms, enabling manufacturers to anticipate potential problems before they occur. By analyzing patterns and trends in the data, these systems can predict equipment malfunctions, production bottlenecks, or quality issues, allowing manufacturers to implement preventive measures and reduce downtime.

This real-time feedback loop not only enhances the efficiency of quality control processes but also helps optimize overall production performance.

Challenges and Considerations

Initial Setup and Training of AI Models

While AI-powered image recognition APIs offer significant advantages for quality control in manufacturing, one of the key challenges is the initial setup and training of AI models. For these systems to function effectively, they require a substantial amount of data to train the models accurately. Manufacturers must provide large datasets of labeled images, representing both normal products and defective ones, to help the AI learn to distinguish between acceptable and faulty products.

This training process can be time-consuming, as the AI needs to analyze various examples to achieve the desired accuracy. Depending on the complexity of the production line, it may take weeks or even months to fully train the model. Additionally, manufacturers must invest in regular updates to keep the models current as products, components, and processes evolve. Despite this initial time investment, once the AI model is trained, the long-term benefits in speed, accuracy, and efficiency outweigh the setup effort.

Edge Cases and Limitations

Although AI-powered image recognition APIs are highly effective, there are still edge cases and limitations where human intervention may be necessary. AI systems can struggle with extremely complex or ambiguous defects that do not fit neatly into the predefined categories of acceptable or defective products. For instance, certain rare or subtle product defects, such as a slight change in material texture, may be too ambiguous for AI to classify confidently without human oversight.

Moreover, environments with unpredictable variables—such as irregular lighting conditions or unusual product orientations—can challenge the AI system’s ability to maintain accuracy. In these situations, human inspectors are still needed to make subjective decisions or to verify borderline cases where AI may provide inconclusive results. As AI technology continues to evolve, it will become more adept at handling these complex scenarios, but for now, a hybrid approach combining AI and human expertise remains the best practice.

Data Privacy and Security Concerns

As manufacturers increasingly adopt cloud-based AI solutions, data privacy and security concerns become critical considerations. The vast amounts of sensitive data generated during the quality control process—such as proprietary product designs, manufacturing processes, and defect data—must be protected from unauthorized access or breaches. When using cloud-based image recognition APIs, manufacturers need to ensure that their data is securely stored and transmitted, especially if the data includes confidential or regulated information.

To address these concerns, manufacturers should work with AI providers that offer strong data encryption and adhere to industry standards for cybersecurity. It’s also important to verify that the AI provider complies with local and international data protection regulations, such as GDPR or CCPA, depending on the region. In some cases, manufacturers may prefer to use on-premise AI solutions to maintain complete control over their data and ensure maximum security.

Future of AI Image Recognition in Manufacturing

Advances in AI Model Training and Performance

As the manufacturing industry continues to evolve, so does the technology behind AI-powered image recognition. One of the most promising developments is the improvement in AI model training efficiency and accuracy. Recent advances in machine learning algorithms and computational power have significantly reduced the time required to train AI models, enabling manufacturers to deploy these systems faster than ever before. Additionally, with the advent of transfer learning and pre-trained models, manufacturers can leverage existing AI models and adapt them to their specific needs with far less data, speeding up the implementation process.

These improvements not only enhance the speed of deployment but also lead to greater accuracy in defect detection and quality control. AI models are becoming more adept at recognizing subtle defects, handling variability in production environments, and maintaining high levels of accuracy across diverse product lines. As AI continues to evolve, the models will become more robust, further minimizing errors and maximizing efficiency.

Enhanced Predictive Maintenance and Automation

The integration of AI-powered image recognition with predictive maintenance systems represents a major leap forward for manufacturers. By analyzing the data gathered through image recognition, AI can predict equipment failures and detect defects earlier in the production process, before they become critical issues. This capability allows manufacturers to perform maintenance only when necessary, reducing unplanned downtime and saving costs on unnecessary repairs.

AI's role in predictive analytics also extends to identifying patterns in production that might indicate future quality issues. By recognizing early signs of equipment wear or process inefficiencies, AI can alert operators to potential problems, enabling them to take corrective action proactively. This predictive automation not only improves overall equipment effectiveness (OEE) but also helps maintain consistent product quality, reducing waste and improving productivity.

AI for Customization and Mass Personalization

As consumer demand shifts towards mass personalization and custom-made products, AI-powered image recognition is poised to play a crucial role in supporting more complex and personalized manufacturing processes. Traditional quality control systems are typically designed for mass production, but AI's ability to adapt and learn makes it ideal for customization. Whether manufacturers are producing one-off items or small batches of highly personalized products, AI systems can be trained to recognize the unique features of each custom item and ensure that they meet precise specifications.

This adaptability positions AI-powered image recognition as a key enabler for the future of flexible manufacturing, where manufacturers can switch between different product lines or customize individual products without compromising quality. As the demand for personalization grows, AI systems will become essential for maintaining the same level of precision and quality control across a diverse range of products.

Conclusion

The integration of AI-powered image recognition APIs into manufacturing quality control processes has brought about a significant transformation. By offering unparalleled accuracy in detecting defects, ensuring efficiency in real-time inspections, and reducing costs associated with manual labor and errors, AI has proven to be a game-changer for manufacturers seeking to maintain high product standards. Whether it's surface inspection, assembly verification, or packaging and labeling checks, AI enhances the precision and speed of these critical processes, driving higher quality and consistency across production lines.

As the manufacturing landscape continues to evolve, adopting AI-powered image recognition technology is no longer just an option—it’s a necessity for staying competitive. The ability to quickly integrate these APIs into existing systems, coupled with the flexibility of cloud and on-premise solutions, makes AI more accessible than ever. By leveraging this technology, manufacturers can not only improve quality control but also unlock new opportunities for innovation, customization, and predictive maintenance.

Call to action: Manufacturers looking to stay ahead in today’s competitive market should explore the potential of AI-powered image recognition APIs. By integrating AI into quality control processes, businesses can improve product quality, reduce costs, and optimize production efficiency. Now is the time to invest in AI technology and position your company for success in the rapidly evolving world of smart manufacturing.