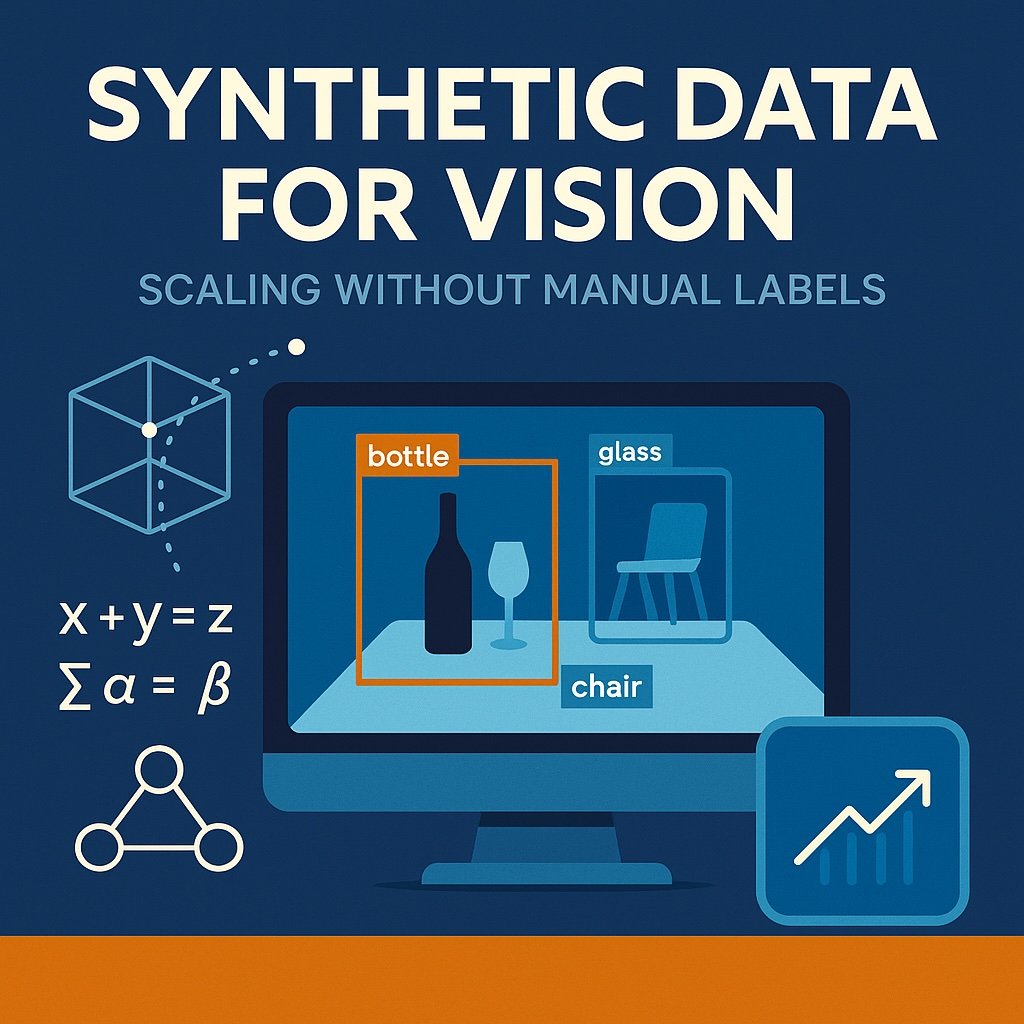

Synthetic Data for Vision: Scaling Without Manual Labels

Manual data labeling is one of the most expensive and time-consuming barriers to scaling computer vision — and it's no longer sustainable. Synthetic data offers a smarter alternative: algorithmically generated images with built-in annotations, enabling faster model development, lower costs, and full compliance with modern data privacy regulations. In this article, we explore how synthetic data is transforming industries like retail, manufacturing, and mobility, and why forward-thinking executives are adopting it as a core component of their AI strategy.

Green Manufacturing Scores via Defect-Free Vision

AI-powered vision inspection is helping manufacturers cut defects, reduce waste, and hit sustainability targets — all without major overhauls. By catching flaws in real time, factories save energy, materials, and money while improving ESG scores. This post explores how cloud-based vision APIs and smart deployment strategies make defect-free, greener production not only possible — but profitable.

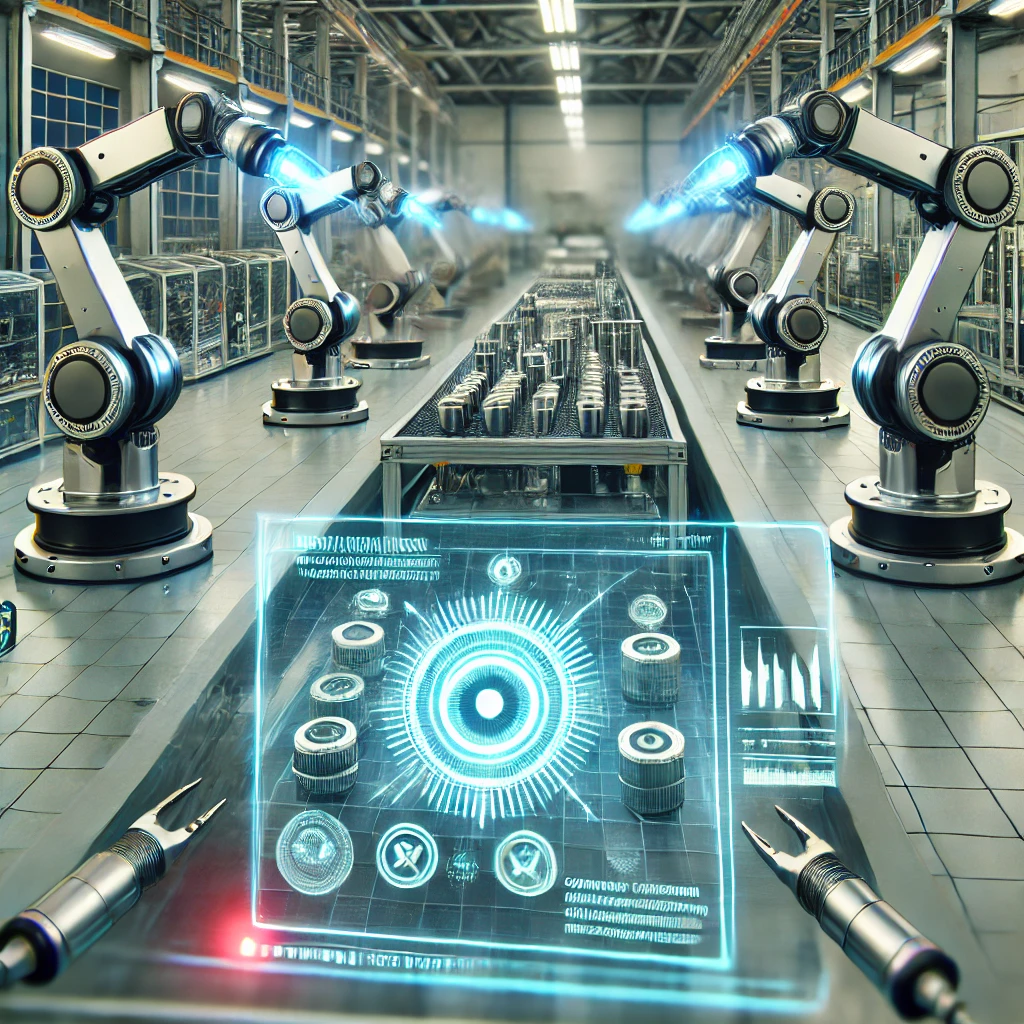

Industrial Inspection: From Cloud to Factory Floor

From micro-cracks in steel to mislabeled food packaging, today’s production lines demand more than human eyes can handle. Modern industrial inspection is evolving — powered by rugged cameras, smart edge devices and AI models that go beyond pass/fail to deliver real-time, score-based insights. In this blog post, we explore how manufacturers are moving from cloud prototypes to factory-floor deployment, using vision systems that adapt, learn and scale. Whether you're launching your first pilot or optimizing a mature line, this guide maps out the steps toward zero-defect manufacturing.

Top AI Trends for the Repair & Maintenance Industry in 2025

The repair and maintenance industry is undergoing a major transformation, driven by AI-powered automation, predictive analytics and real-time monitoring. Traditional maintenance methods, which relied on scheduled servicing and manual inspections, are being replaced by smart, data-driven solutions that improve efficiency, reduce costs and enhance safety.

In 2025, key AI trends — predictive maintenance, computer vision inspections, robotics, IoT connectivity and augmented reality training — are helping businesses anticipate failures before they happen, automate routine tasks and optimize resource allocation. By integrating AI-driven object detection, OCR and IoT-powered analytics, companies can minimize downtime, extend equipment lifespan and reduce operational risks.

While off-the-shelf AI APIs provide quick solutions for enhancing maintenance processes, custom AI solutions offer even greater long-term benefits by tailoring automation to industry-specific needs. Companies that embrace AI today will future-proof their operations, ensuring sustainability, profitability and a competitive edge in the years ahead. The time to innovate is now.

Image Processing & Drone Imagery: Multi-Industry Insights

Drones have revolutionized data collection across industries, but raw aerial imagery alone isn’t enough — it’s the power of AI-driven image processing that turns this data into actionable insights. From agriculture and environmental monitoring to construction, security, and disaster management, AI-powered analysis enhances decision-making, automates workflows, and improves operational efficiency.

This article explores how AI transforms drone imagery, the key tools and techniques used for object detection, OCR, and background removal, and the strategies businesses can implement to integrate AI-powered drone analysis into their existing systems. We’ll also examine emerging trends such as on-drone edge computing, real-time emergency response applications, and breakthroughs in deep learning for precise object recognition.

As AI technology evolves, organizations that invest in AI-powered drone solutions will gain a significant advantage—streamlining operations, reducing costs, and unlocking new possibilities for automation. Whether using pre-built APIs or custom AI models, the future of drone imagery is being shaped by intelligent image analysis. Dive in to discover how your business can harness these innovations to stay ahead.

Top AI Trends in the Oil and Gas Industry for 2025

As the oil and gas industry faces increasing pressure to improve efficiency, reduce costs and meet environmental regulations, AI-powered technologies are transforming operations at every level. From predictive maintenance that prevents equipment failures to computer vision systems that enhance worker safety and environmental monitoring, artificial intelligence is reshaping how energy companies explore, extract and manage resources.

In 2025 and beyond, the integration of AI-driven analytics, automation and real-time monitoring will be key to staying competitive in a rapidly evolving energy landscape. Companies that strategically adopt AI solutions will not only reduce operational risks and optimize production but also gain a significant advantage in sustainability and cost-efficiency.

The future belongs to those who embrace AI-driven innovation — leveraging intelligent automation, data-driven decision-making, and custom AI solutions to unlock higher profitability, improved safety and long-term resilience in the oil and gas sector.

Quality Control 2.0: Detect Defects Faster with Deep Learning Models

Quality control is entering a new era with the power of deep learning. Traditional inspection methods, limited by human error and inefficiency, are being replaced by AI-driven manufacturing solutions that deliver unparalleled speed, precision and scalability. From detecting micro-defects in electronics to automating label inspections in pharmaceuticals, defect detection automation is transforming industries. Explore how deep learning revolutionizes quality control, its applications across sectors and why adopting AI-powered solutions is key to staying competitive in today’s fast-paced manufacturing world. The future of quality control is here — are you ready to embrace it?

Transforming Quality Control with Computer Vision

Traditional quality control methods struggle to keep up with the demand for precision and efficiency. Computer vision is transforming this landscape by automating inspections, detecting even the smallest defects and ensuring product consistency across industries. From real-time monitoring on production lines to customized solutions for niche markets, this AI-powered technology is setting new standards for quality assurance. Discover how computer vision is shaping the future of quality control and why adopting this innovation is essential for staying competitive in an evolving market.

How AI-Powered Image Recognition APIs Enhance Quality Control in Manufacturing

AI-powered image recognition APIs are revolutionizing quality control in manufacturing by delivering unparalleled accuracy, efficiency, and cost savings. These advanced systems automate defect detection, assembly verification and packaging inspections, ensuring consistent product quality and reducing human error. With real-time data analysis and seamless integration into existing workflows, AI-driven quality control is helping manufacturers stay competitive in today’s rapidly evolving market. Discover how integrating AI-powered image recognition can optimize your production process and improve product standards.